Call

Recently, the official website of the Ministry of Industry and Information Technology announced the list of 2025 Excellence-Level Smart Factory projects. The "New IoT Mobile Display Module Intelligent Manufacturing Demonstration Plant," established by Bengbu K&D Technology Co., Ltd., a subsidiary of CSG Holding Co., Ltd., has been successfully included in the list. This achievement marks the company's entry into the national leading echelon in intelligent manufacturing and digital transformation.

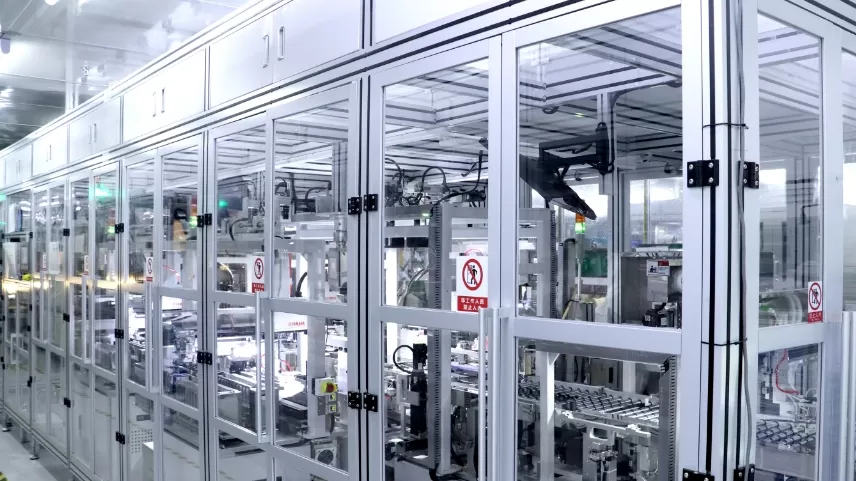

Centered on a 5G private network, the plant has established a high-speed, low-latency, and highly reliable industrial internet environment, achieving full coverage across office areas, production workshops, and storage zones. With network availability reaching 100%, the system can support concurrent connections for over 2,000 terminal devices. Through the deployment of UPF equipment and multiple 5G base stations, seamless signal coverage has been realized across the campus, enabling end-to-end interconnection of the entire workflow—from raw material warehousing to finished product delivery—spanning personnel, machinery, materials, methods, and environment.

Leveraging digital twin and 3D visualization technologies, the plant monitors equipment status, material flow, and environmental parameters in real time, enabling dynamic oversight and intelligent scheduling of the production process. The connectivity rate for key equipment exceeds 91%, with data transmission speeds reaching 1.2 Gbps and end-to-end communication latency controlled within 15 milliseconds. This significantly enhances production coordination and real-time responsiveness, providing a robust technological foundation for the intelligent manufacturing and efficient delivery of high-end display modules.

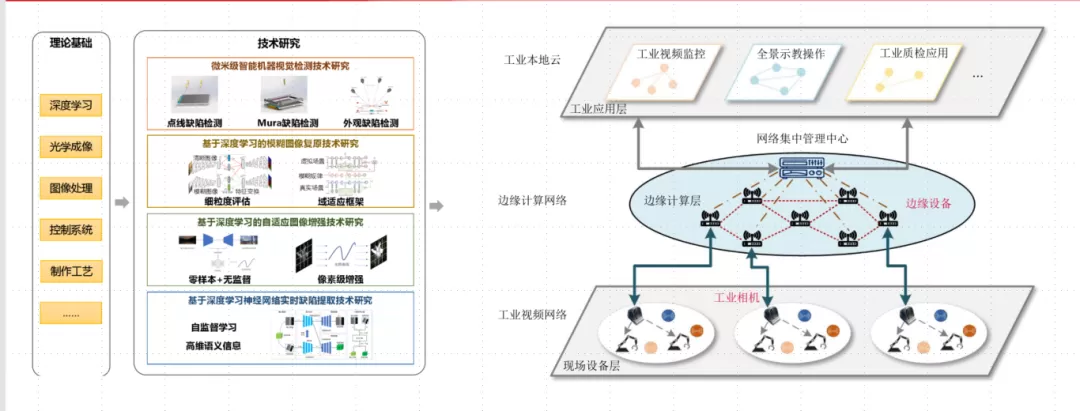

In quality control, the company has independently developed a fully automated AOI intelligent inspection system, integrating high-definition CCD vision and multi-scenario AI algorithms. This system comprehensively conducts online inspections for various process parameters, including module appearance, light transmission, lamination, and backlight performance. Capable of accurately identifying micron-level defects, the system automatically rejects defective products in real time and continuously optimizes detection accuracy and adaptability through self-learning algorithms. The defect detection rate has been elevated to over 99.5%, with the missed detection rate kept below 0.5%. Inspection time per unit is just 14 seconds, achieving an efficiency more than three times higher than manual inspection.

Furthermore, utilizing a digital quality platform, the plant has implemented closed-loop management of quality information—from customer requirements to production feedback—significantly shortening the response cycle for quality issues and ensuring high product consistency and reliability.

Embracing green manufacturing principles, the company has implemented an Enterprise Energy Management System (EMS) to monitor and optimize energy consumption across 580 sets of equipment in 12 workshops. By adopting energy-saving technologies such as variable frequency drives for water pumps and cooling towers, as well as load interval optimization, the plant has effectively reduced comprehensive production energy consumption. In December 2024, it was recognized as a National Green Factory.

In logistics and supply chain management, through the deep integration of a Warehouse Management System (WMS), Automated Guided Vehicles (AGVs), and third-party logistics management platforms, the plant has automated storage operations, optimized distribution routes, and enabled full traceability of transportation processes. This has significantly improved inventory turnover rates, order response speed, and accuracy.

The project also actively shares its intelligent manufacturing expertise, driving collaborative digital transformation among multiple upstream and downstream partners and initially fostering a green, efficient, and synergistic new manufacturing ecosystem.

This inclusion in the national Excellence-Level Smart Factory list represents high recognition of Bengbu K&D Technology's innovative practices in the field of intelligent manufacturing. It will further propel the intelligent, green, and high-end development of CSG Holding Co., Ltd.'s new display materials and module manufacturing segment. Moving forward, the company will continue to increase investment in smart factory development, with artificial intelligence as the core driver, to build an industry-leading digital base for the intelligent display industry. It aims to establish a "Lighthouse Factory," providing solid support for Bengbu's "New Display Industry Cluster" and contributing CSG's strength to the high-quality development of manufacturing in China.

Contact Info

Let's discuss how K&D's display solutions can bring your next-generation product to life.

Call

Add